Fiber composites such as CFRP (carbon fiber reinforced plastics) have become indispensable in modern aerospace engineering. They enable lightweight, highly resilient, and aerodynamically optimized structures. At the same time, however, the requirements for quality assurance, documentation, and process integration in production are increasing.

Porosity, air inclusions, and near-surface defects in particular must be detected early on—reliably, reproducibly, and across large areas.

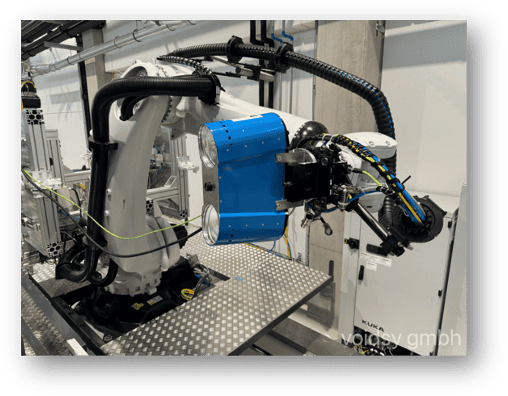

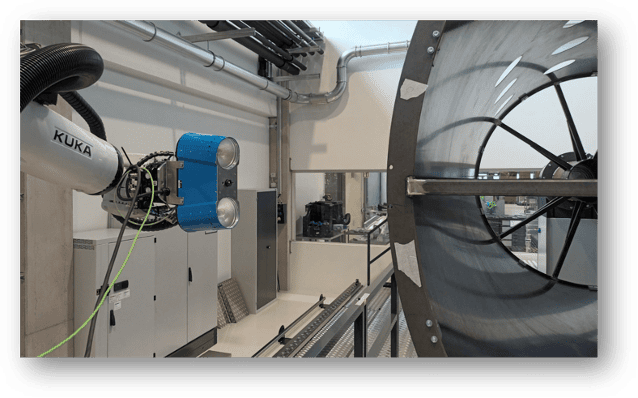

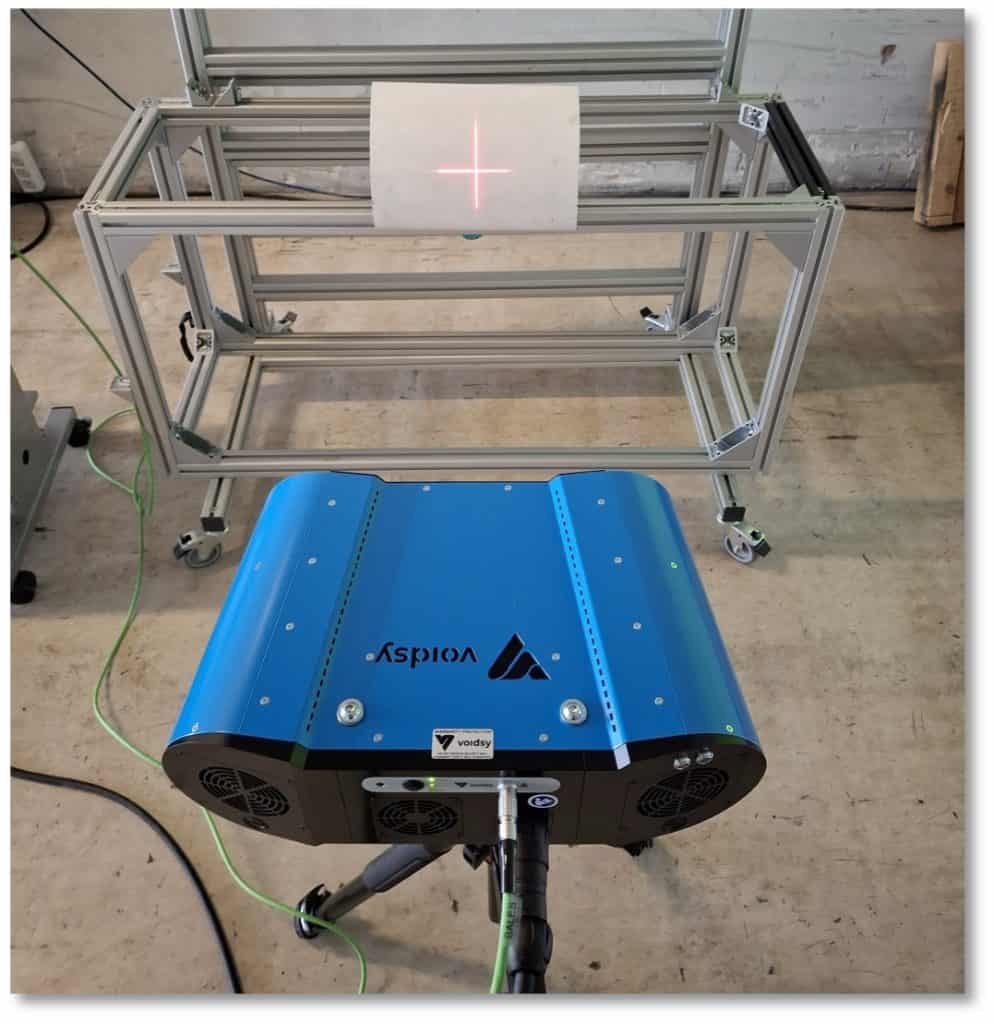

The voidsy V-ROX system provides a solution that automatically tests large composite structures using robotics directly in the manufacturing process.

One example of application is the inspection of a large, curved CFRP aerospace structure. The goal was to capture the entire component surface efficiently and with high measurement stability.

System parameters:

Within just 90 minutes, more than 300 measurement fields were recorded and the entire area was systematically checked.

The results show:

This makes the system particularly suitable for automated quality assurance in aerospace production, where large structures need to be inspected quickly and reproducibly.

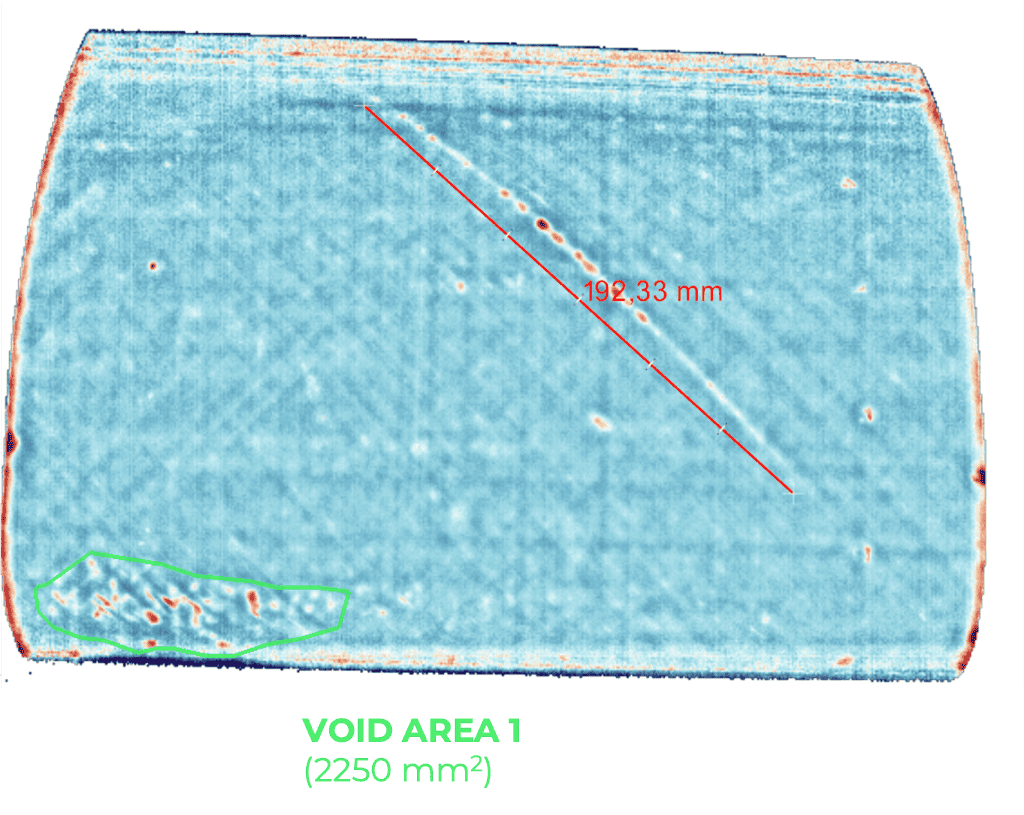

Another example is the inspection of a leading-edge component. Precise defect detection is crucial, especially for aerodynamically sensitive components.

System parameters:

Several areas with porosity agglomerations were clearly identified. In addition, the defects were not only detected, but also measured and geometrically characterized. Among other things, the following were recorded:

This quantitative evaluation enables a well-founded quality assessment directly in the production process.

In aerospace, components are costly and critical to safety. Defects that are detected late in the process lead to high rework costs or scrap.

Robot-assisted inspection with voidsy therefore offers decisive advantages:

Quality assurance is thus evolving from a reactive control step to an integrated, data-based component of modern aerospace production processes.

voidsy gmbh | Magazinstraße 18, 4600 Wels, AUSTRIA | [email protected] | Company registration: FN 587365 y | Managing Director: Dr. Holger Plasser